The European Project STEEL S4 EV, funded by the Research Fund for Coal and Steel (RFCS) has successfully completed the first half of research and development activities. This item has coincided in the time with the presentation of the design of the second vehicle of the project: the threewheeler. The design presents several parallelism with the four wheels vehicle defined in the first stages of the project. The objectives behind this similarity are multiple, on one hand to simplify and make cheaper the manufacturing process, making possible to assembly both vehicles in the same assembly line, on the other hand to warranty the same level of integral safety as in the four wheels vehicle.

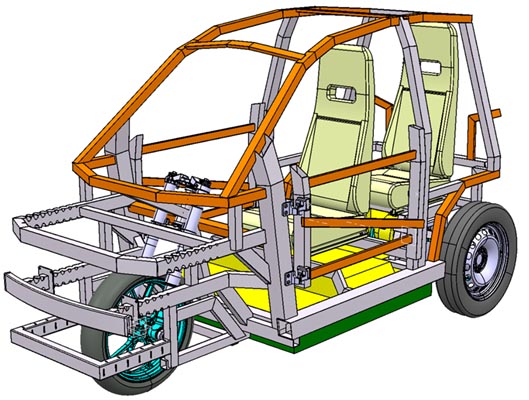

The solution adopted for the threewheeler is a two in line seats vehicle, with one wheel in the front, the electric motor in the rear axle, under the rear seat, and the battery pack under the front seat. The structure of the vehicle is made of different grades of Advanced High Strength Steel, where the geometry of the tubes and their thickness have been optimized to maximize the energy absorption in the frontal part of the vehicle and to warranty the undeformability of the safety cell, where the occupants are allocated.

In order to get this target, in parallel to the optimization of the crashworthiness through the finite elements methodology, advanced research is been done about the optimization of the welded joints of the advanced high strength steels. In every welding joint, not only the weld seam, but also the heat affected zone, suffers an important loss of mechanical properties due to the melting and uncontrolled cooling of the material. In the case of the Advanced High Strength Steels, this loss of properties is still more critical due to the special characteristics of the material. One of the objectives of STEEL S4 EV Project is to optimize the welding parameters, to improve the heat treatment of the joints in order to improve the static, dynamic and fatigue behavior of the welding joints of the complete structure of both vehicles, the three wheeler and also the four wheels vehicle.

In April, it has been held the Midterm Review Meeting of STEEL S4 EV Project, between the Project Coordinator, the Project Officer and some technical experts from the TGA 4. After a successful meeting, the activities of the project go on with the focus on the prototype manufacturing and the preparation of the different tests.